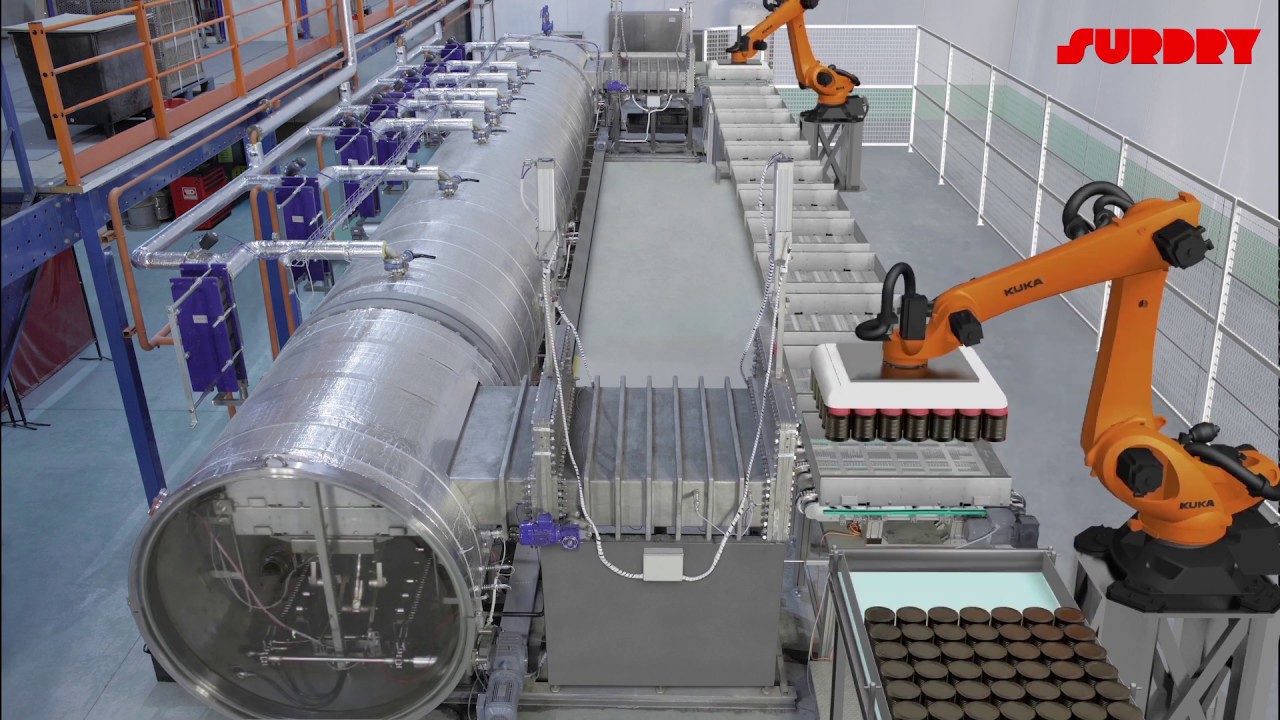

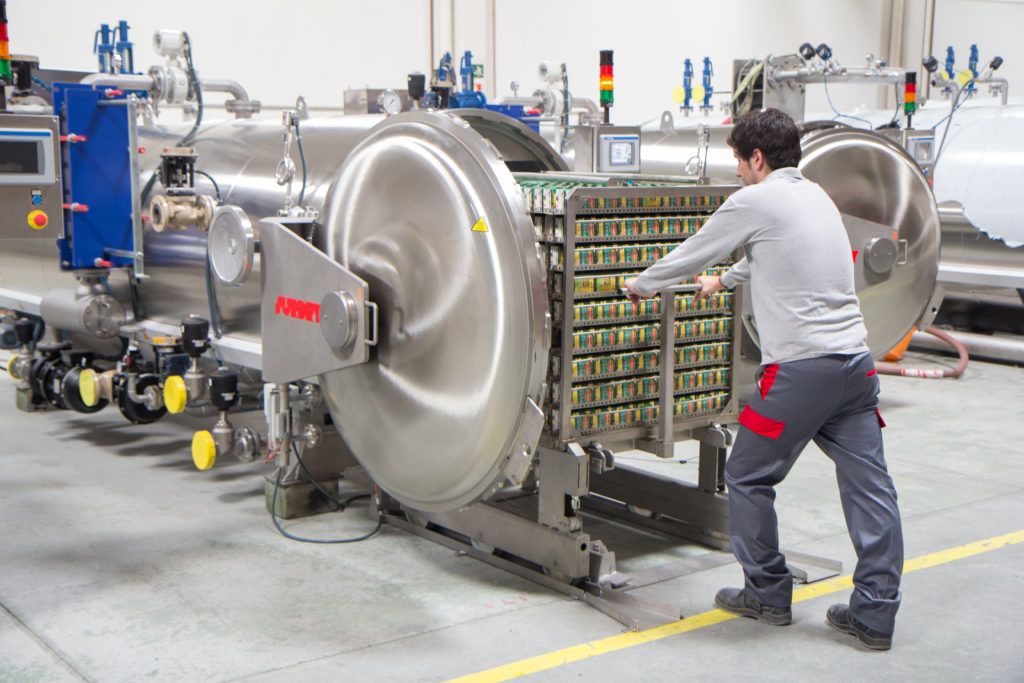

Surdry will accompany you in the digital transformation of your retorts

Industry 4.0 has become a priority for the food sector, a must in a highly competitive global market. At Surdry, we know that the digital transformation is essential in order to increase productivity[...]

.jpg)