During the retorting process, containers expand and contract due to the temperature and pressure changes inside the vessel and in the container itself. It has been proved that, in some cases, it is likely that small drops of retort process water can go into the containers through any gasket or weak lid that move during expansion and contraction. In most cases, this has been found after a recall made for contaminated products, late enough when the product is in advanced stages within the consumer chain.

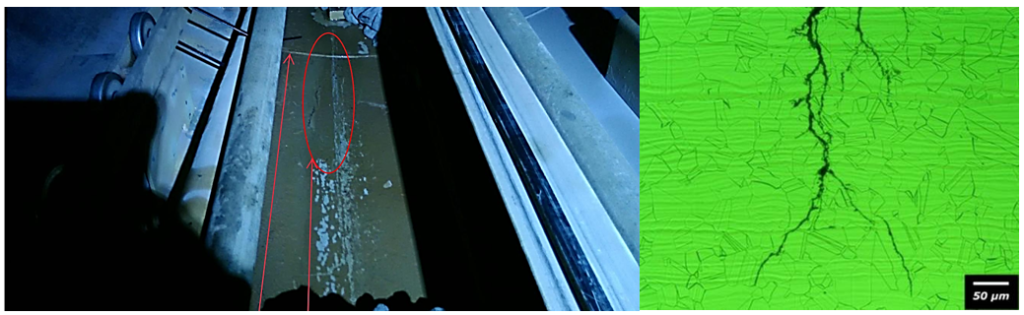

Therefore, good practices in Food Industry have ruled the use of chlorinated treated water in retorts for sterilizing the products. However, chlorine is the main cause of stress corrosion cracking (SCC) of austenitic stainless steel. Cracks in retorts will result in a vessel failure after years of exposure, causing the replacement of the retort, if found in time, or in a more dangerous scenario that can put persons and production safety at risk if not detected.

The resistance of austenitic stainless steels to SCC is related to the nickel content of the steel. The most susceptible austenitic grades have nickel contents in the range of 8 to 10 wt%. Therefore, standard grades such as 304/304L and 316/316L are very susceptible to this mode of attack. The typical crack morphology for chloride stress corrosion cracking consists of branched transgranular cracks.

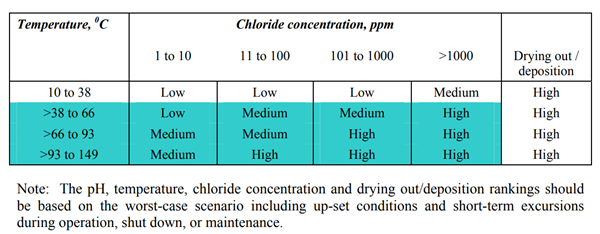

In retort environments, high temperatures can produce a local build-up of aggressive corrosive substances, such as chlorides and the H+ ions, resulting in conditions that are substantially more aggressive. At common sterilization conditions, the level of chlorides required to produce cracking is relatively low. Failures have been reported in environments with as little as 10 ppm chlorides. The risk of attack can be seen in the following table:

Surdry highly recommends to track and control process water parameters within the following ranges:

- pH: 5,5 - 8,0

- Chlorine concentration: máx. 1-1.5 ppm

- Total hardness 3 – 5 ºdH or 54 - 90 ppm

If you have any concerns regarding your water quality and any impact it can cause on the retort, we recommend asking for advice from any approved Material Research Center or Specialist.

Sources:

https://www.hse.gov.uk/research/rrpdf/rr902.pdf