Overpressure is the quiet force that keeps modern non‑can packages intact during sterilisation. But what exactly is it, when must you apply it, and why should you care? This article breaks the concept down for plant engineers, quality managers and curious marketers alike.

What is overpressure?

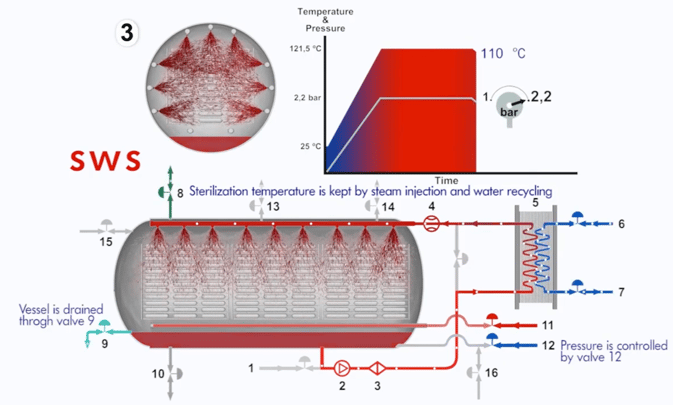

Inside a retort the vessel is pressurised by steam, compressed air, or a measured blend delivered by a modulation valve. Overpressure is the portion of that total vessel pressure above the saturated‑steam pressure required to reach the target temperature. At 121 °C (≈ 1.2 bar g), operating at 2.2 bar means 1.0 bar of overpressure. That extra fraction has almost no influence on lethality, it exists to protect the package.

Why does it matter?

1. Package integrity

Pouches, PP trays, glass jars with plastic lids and lightweight cans deform well below 2 bar. External overpressure keeps them from bulging, paneling or blowing seals. A 300 g tuna pouch, for instance, may burst at just 0,4 bar internal pressure; holding the vessel at 2.0 bar overpressure prevents that failure.

2. Seal reliability

Polymer layers are weakest when hot. A cushion of air holds seams tight until they cool, cutting post‑process leak rates by an order of magnitude.

3. Water & energy efficiency

Added pressure raises water saturation temperature, improving heat transfer. Plants often drop spray flow by 15 % yet hit the same come‑up time, saving water and steam.

4. Operational safety

Positive pressure to ambient eliminates implosion risk and dampens the flashes created when hot steam meets cool water.

When do you need it?

| Package type | Heating stage | Cooling stage |

| Rigid metal cans | Low | Medium |

| Glass jars (lug twist) | Medium | High |

| Semi-rigid PP cups | High | High |

| Flexible pouches | High | High |

Required magnitude depends on headspace volume, wall strength and retort design. Side‑spray systems often need less air; saturated‑steam vessels switching to water cooling need more to stay above 0 bar g.

Common pitfalls

- Adding air too fast: A sudden 0.5 bar jump can distort seals. Ramp in steps of ≤ 0.2 bar min.

- Ignoring seasonal water: Winter mains water collapses retort pressure; adjust set‑points.

- One recipe for all SKUs: Even a lighter lid changes the balance—validate each package.

- Valves out of calibration: A sticky solenoid causes oscillations that fatigue seals.

Best-practice checklist?

- Establish the minimum overpressure that prevents defects for every format.

- Calibrate sensors twice a year

- Store the pressure curve with every batch for audit traceability.

How to set the right value

Start with the minimum vessel pressure that keeps the weakest package dimensionally stable during heating, then add a 0.1 bar safety margin. During cooling, target at least 0.5 bar above peak internal product pressure to cover the worst‑case combination of cold water and hot headspace gases. Record both values and lock them in the recipe for repeatability.

This process is easier to understand when visualized. The following diagram shows how pressure and temperature are controlled throughout the sterilization cycle in a Surdry SWS retort system, ensuring package stability across all phases:

📺 Watch it in action! This video shows how overpressure and temperature evolve during the sterilization cycle inside a Surdry retort system. It's a clear example of how our technology ensures stable, repeatable conditions for packaging integrity.

Final thoughts

Overpressure is a core parameter that determines whether a product leaves the retort shelf‑stable and marketable. The modest cost of compressed air and instrumentation is dwarfed by the savings in rework, returns and brand reputation. Give overpressure the attention it deserves your package, and your customer will thank you.

💬Learn more about how our retort systems support high-performance sterilization across multiple packaging formats, and contact our team to explore how Surdry’s autoclaves and automation solutions can adapt to your packaging and production needs.