In today’s economy, the food industry calls for larger, high capacity retorts sizes on the same or smaller plant footprints. In addition to high capacity, plants need the ability to provide flexible processing techniques based on ever expanding container types. Globally, most modern retort technologies are based on steam as the primary source of heating but steam alone cannot provide for an adequate process for flexible and some semi-rigid containers. At saturation temperature, steam provides overpressure at approximately 1 bar or 15psi at sea level. Simply stated, temperature is relative to pressure in a pure saturated steam process. A pure saturated steam process is not an overpressure retort process. To achieve an overpressure process, compressed air injection is required to raise the vessel pressure independently of the steam saturation pressure to a set-point that will counterbalance the pressure developed inside a container, when the food content and headspace within the container is raised to process temperature. Maintaining the D/P is critical throughout the entire heating and cooling slope to prevent degradation of the seal and/or body of the flexible container. Flexible or delicate food containers require higher external pressure to counterbalance the internal pressure to prevent deformation or risky seal damage.

In today’s economy, the food industry calls for larger, high capacity retorts sizes on the same or smaller plant footprints. In addition to high capacity, plants need the ability to provide flexible processing techniques based on ever expanding container types. Globally, most modern retort technologies are based on steam as the primary source of heating but steam alone cannot provide for an adequate process for flexible and some semi-rigid containers. At saturation temperature, steam provides overpressure at approximately 1 bar or 15psi at sea level. Simply stated, temperature is relative to pressure in a pure saturated steam process. A pure saturated steam process is not an overpressure retort process. To achieve an overpressure process, compressed air injection is required to raise the vessel pressure independently of the steam saturation pressure to a set-point that will counterbalance the pressure developed inside a container, when the food content and headspace within the container is raised to process temperature. Maintaining the D/P is critical throughout the entire heating and cooling slope to prevent degradation of the seal and/or body of the flexible container. Flexible or delicate food containers require higher external pressure to counterbalance the internal pressure to prevent deformation or risky seal damage.

"[...] the food industry calls for larger, high capacity retorts sizes on the same or smaller plant footprints."

Air, yes but…

While air is good to raise to set-point pressure higher than pressure achieved by saturated steam, with air’s low thermal conductivity, it works against what we are striving for, heat transfer and temperature uniformity. Cans are nested so tightly against each other that air bubbles are difficult to expel from the sterilizer. Eliminating the air trapped in between cans is accomplished with a vent phase by flushing the air from the retort with steam to completely replenish the vessel with steam thus eliminating any air. This is a difficult step, especially when large baskets are loaded with thousands of small cans. Air pockets around or next to cans are most likely to create insulation which will create lower than expected process temperatures and is the cause of dangerous sterilization deficiency if the sterilizer or the vent phase is not tested, validated, and locked down in the sequence logic of the software.

Steam alone, yes but…

As mentioned above, saturated steam retorts can only provide a single pressure value equivalent to its saturation temperature and is usually much less than the pressure built inside the container. For this reason, the integrity of the food container will rely on its own strength to resist the inside versus outside pressure differential. Hence, using saturated steam process for easy peel lids, plastic, pouches, glass and chubbs (casing only) containers is not a valid option. This is a huge downside which made thousands of saturated steam retorts obsolete with today’s new container offerings. Although several have been replaced over the last three decades for more versatile air counter-pressure retorts, it does not solve the problem of flexibility. Most European food industries handle both strong and flexible containers in single plants and were and still are being subsequently led to use retorts with air counterpressure. Those retorts are just fine as long as the basket volume is not higher than 800 liters (211 gallons)

However, many saturated steam retorts a, re still utilized worldwide for a number of good reasons. Although energy efficiency may not be one, due to the relatively high steam input requirement, the complete replacement of air in the vessel (venting) followed by steam saturation is the best guarantee of fast and uniform heating. No other retort heating method is able to achieve even temperature +/-1 ºC in less than 15 minutes in a cubic meter (1000 liters or 264 gallons) size basket in between the interstices of 20 or more layers of tightly packed small cans.

Saturated steam retorts are also more forgiving than steam-air retorts when the can quality, particularly the surface protection, is not good enough. Modern technologies, either using high speed steam-air circulation with fan or water mixers, have often been the cause behind deterioration of poorly protected can lids or seams in the form of lacquer erosion.

Container diversity in a single multifunctional retort

No more “buts.” (Best of both process worlds)

Surdry invented in the early 80’s the latest industry standard where the air is mixed with steam by the action of superheated water spray, as an evolution of the mix by a fan. Both technologies reduced largely the energy cost of operation inherent to full water immersion retorts. Water immersion had been the only method to sterilize glass containers and pouches up till then.

Since more and more customers are requesting Surdry to offer them retorts with basket volumes beyond the cubic meter and able to work with all small and big cans, steel or aluminum, EOE or easy-peel lids, foil or plastic pouches, etcetera, we turned our heads to the traditional saturated steam working method and looked into the best method to come up with a more versatile design one step beyond the rest.

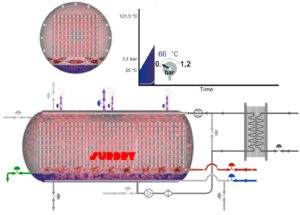

Our universal Steam-air and Water Spray (SWS) with finest air counter-pressure proportional control has now become “Hybrid” to incorporate modernized saturated steam process with the highest heating power ever. The biggest jumbo size Surdry retorts are now available to work with small cans and pouches without compromising process safety or quality. The user will now be able to make their choice of which process delivers best performance for the given container on one sterilizer platform. State of the art controls ensure each type of container is always treated with its ideal process method. The HSWS (Hybrid Steam and Water Spray) series is now an industry proven Surdry reality.

Our multiport manifold/nozzle configuration in conjunction with multiple steam injection points promote the fastest possible come up times (CUT). For example, 208x208 can, 4.6 oz, 130 gr., CUT in 10 Minutes with a Vent Temperature of 220°F (105 ºC).

An Engineered Hybrid Sterilizer, not an add on to a Saturated Steam design

- Available in 1500mm Dia.

- 4,6 and 8 baskets or tray positions

- Single or Dual Door configurations

- Stainless Steel 304 (Standard), 316 available

- SteriNet/SteriPro Control / Allen Bradley Hardware

- ICON Control/Allen Bradley Hardware/ 21CFR Part 11 Compliant

- FDA/USDA Accepted