Many different types of retort machines are available in the market and choosing the appropriate one can be a tricky process. Adriana Farris, product manager at Surdry North America, provides five tips to help ease the buying process.

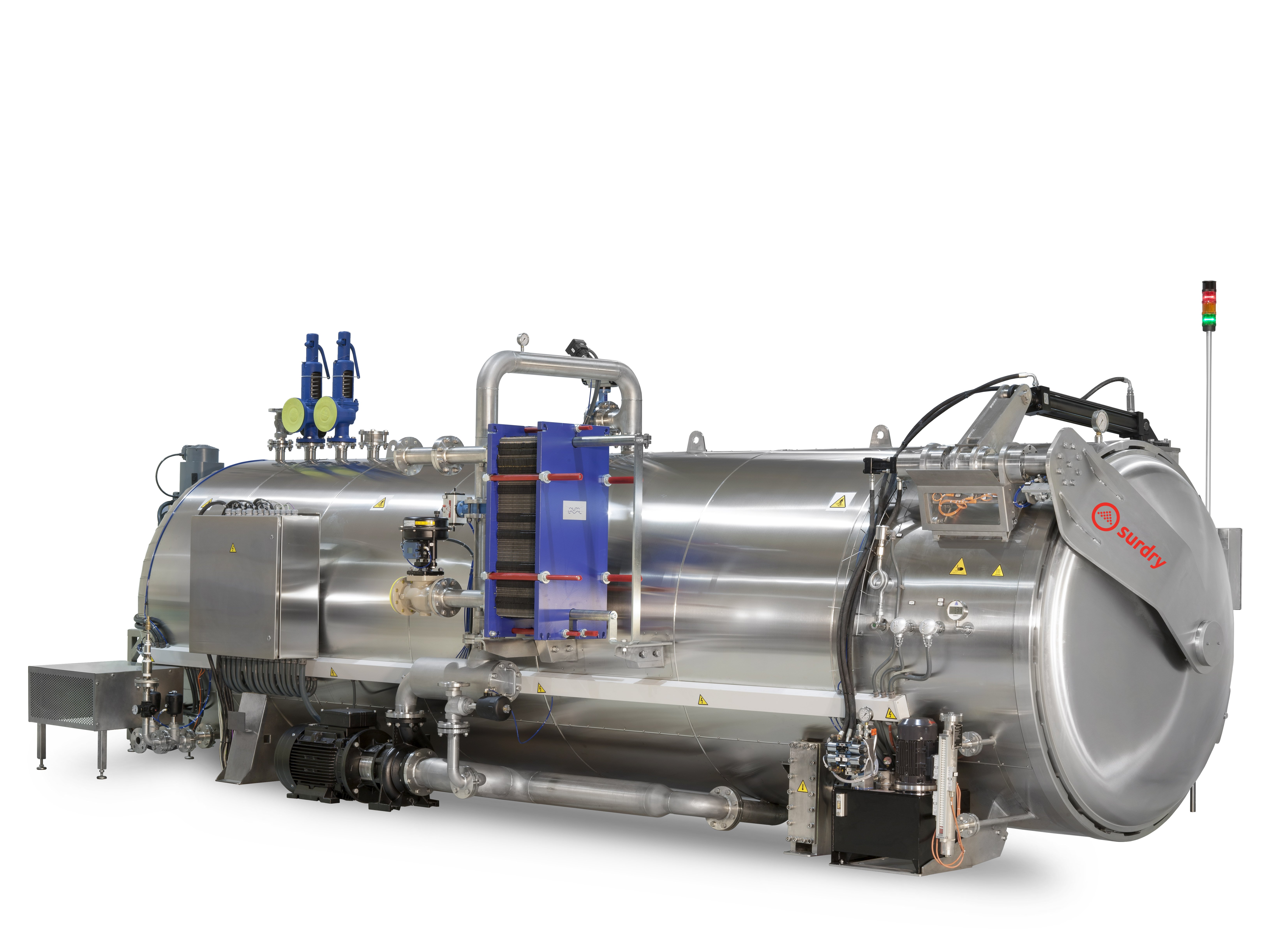

Retorts, also called autoclaves, are key pieces of equipment needed to commercially sterilize food and beverage products after they have been packaged and sealed, ensuring shelf stability. Various types of retorts are available in the market, and understanding their differences can be challenging when determining the best option for a specific product or container. Choosing the right equipment is critical to complying with industry standards and regulations — and more importantly, ensuring food safety and quality

There are several factors to consider before purchasing food retort equipment. Adriana Farris, product manager at Surdry North America (SNA), lists five important things to pay attention to before making your purchase.

1. Processing technology:

There are a few different types of retorts in the market that use different thermal processing methods. One of the most popular and reliable technologies is the Steam Water Spray (SWS), which combines steam and spray of heated water with air-overpressure in the sterilization process. Other technologies include Saturated Steam (SST), Water Spray Heating (WSH) and Cascading Water. Regarding the handling of food and beverage products inside the equipment, one can explore various batch options — including static, rotary and oscillating — or continuous sterilizers.

“It is important to be aware of the different technologies available and evaluate which retort aligns best with your product’s characteristics and processing requirements. For example, products that contain milk can change color if they are sterilized in static retorts rather than agitating retorts. Each type has its advantages and limitations,” Farris explains.

2. Capacity, size and space:

Retorts are available in various sizes and production capacities. The first step is to calculate the desired output — how much you intend to produce per minute (or hour). To achieve this target, you must factor in the sterilization requirements for the food and beverage products processed in the retorts, weekly operational time of the machines and demand for your product. With that information, you can evaluate the retort size and number of units needed for your facility. Finally, you must analyze if there is enough space available for all machines required to meet the desired productivity.

“You need to consider the retort’s footprint, dimensions of your product packaging and any additional space needed to store accessories such as baskets, trays and trolleys. Ensure that all these considerations can be accommodated in the production facility,” Farris says. “This calculation should also consider whether operations will be manual or fully automated.”

3. Control systems:

The control system is the backbone of food retort equipment. It ensures safety, quality and efficiency of the food processing operations. For example, it regulates the temperature and pressure within the retort, monitors if the heat distribution is uniform throughout the machine and duration for which the products are subjected to this heat. These are crucial parts of the sterilization process; not only for safety purposes, but also for regulatory compliance.

“It is important that customers understand the array of their desired retort’s control system features as well as the ease of its operations. This will ultimately facilitate staff training,” Farris says.

She points out that modern control systems are automated, which reduces the risk of human error and deviations from standard parameters in the process. These systems also offer digital data storage capabilities for tracing and tracking processing parameters.

4. Safety:

Farris explains that there are two key safety aspects to consider regarding retort equipment: food and operational safety. Food safety is mostly regulated by retort control systems. To ensure operational safety, it is crucial to review the retort’s safety features — when pressure and temperature levels are within safe parameters it prevents under- or overheating as well as under- or over-pressurization.

Your new retort machine must meet all safety standards and regulatory requirements for your country or region. To operate in the U.S., for example, retort vessels must be certified by the American Society of Mechanical Engineers (ASME).

5. Maintenance and support:

Finally, consider the ease of maintenance, spare parts availability and quality of customer support services provided by the manufacturer before purchasing a retort.

“Understanding that there is reliable support in place is crucial for ensuring the seamless operation of retorts. That will minimize your unplanned downtime and keep your machines running at peak efficiency levels,” Farris says.

She recommends searching for a reputable manufacturer that offers operator training, builds tailored preventative maintenance plans and is committed to minimizing unplanned machine downtime.