Data loggers are wireless instruments that are used to log critical values within the sterilization process, such as temperature, pressure and humidity. Inside the retort, the data logger works as a highly reliable and safe tool to document process measurements. The use of such devices offers numerous benefits and ensures the proper sterilization of products.

Temperature control inside the retort is facilitated

The data logger is located inside the container with foodstuff and logs the temperature values, through the transformation of electrical variables. This data is stored in the device and is downloaded to the computer once the sterilization process is completed. Although data loggers capable of transmitting data in real-time via radio-frequency are already being marketed, their use is not suitable for measuring the temperature inside food containers, as they do not have the necessary measurement requirement level.

Data loggers are characterized as small instruments that operate thanks to a battery. This grants them greater autonomy as opposed to the traditional alternative, the temperature probe, which should be connected via cable to the measurement device and logger.

The product can be monitored with continuous flow systems

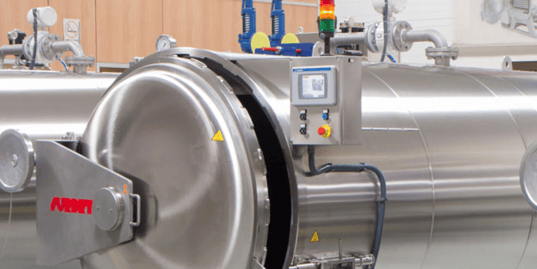

Continuous flow sterilizers are retort systems designed for medium and high production rates. They allow for a higher production speed and also enjoy other benefits, such as increased flexibility in packaging formats and significant energy savings.

In continuous flow systems, the use of cable probes to measure temperature and pressure is not viable. Therefore, in this type of retort, data loggers are not only the most efficient way of controlling data, but they are also the only procedure that is fully reliable.

Food safety of the product is guaranteed

The data logger enables the exact measurement of the temperature and pressure levels reached inside the hermetically sealed packaging at the product’s coldest point. Such information is essential, as it is the way of guaranteeing that sufficient temperature has been reached to destroy harmful micro-organisms.

On the other hand, pressure control protects the integrity of the container and prevents the hermetic seal from breaking during the sterilization process, which is another key element in food safety.

Food quality is preserved in the long term

Monitoring of the sterilization process using a data logger avoids deviations that may affect product quality. This instrument enables critical values set out in the sterilization preparation process to be controlled and any incident to be detected early.

In the preparation process, variables are established, such as the heating ramp rate and the appropriate temperature levels. Depending on the product, a short heating ramp rate will be required to reduce the effects of cooking, or on the other hand, a slow process enables the product to be cooked at the same time as it is being sterilized. Exact and reliable measurement via the data logger is essential to ensure the proper performance of these processes.

The most effective system to monitor data

Data loggers are the most reliable way to control temperature data inside the food containers. These instruments have enough autonomy to perform operations thanks to their battery and they have systems to ensure that data is not lost even if the device runs out of power. Thanks to their design, they are easy to operate and are developed to address the demands of the food industry.

![[Free ebook] Digital transformation in the food industry](https://no-cache.hubspot.com/cta/default/4638724/d5f959b0-65e3-473e-8ddf-c96a1a0966c8.png)